Laser Marking Techniques

techniques

Laser Marking

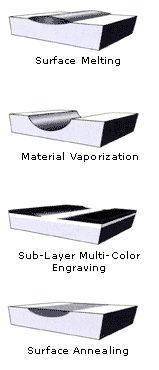

Laser Marking offers impressive benefits over conventional marking methods. Lasers produce a significant amount of energy in a small defined area (as small as .003″). This focused energy is far greater than that achieved by any other process as it heats, melts or vaporizes within selected areas. Lasers can achieve significant contrast by material melting, material annealing or material vaporization, all effects being uniquely permanent. The diagrams to the right further clarify the different effects we can achieve with laser marking.

Today a large variety of materials are being enhanced with laser marking. Virtually all metals, most plastics and a great deal of coated materials are being beautifully and permanently laser marked. Manufacturers of parts unsuitable for laser marking are utilizing laser marked identification plates. These are commonly made of stainless steel, anodized aluminum, brass, steel or adhesive backed plastic.

The flexibility of computer generated graphics and part marking programs quickly becomes your advantage, providing for low set-up cost and fast turn around. Our ability to scan your graphics means high quality and fast delivery, even on complex jobs. Using computer automated programming, we can also statistically code and identify your parts, reducing product identification errors and costly mistakes.